The One Press® Swaging System

A proven process, this unique system is designed to swage steel sleeves onto Flemish eye wire rope slings in just ONE PRESS®! Consisting of the innovative combination of ONE PRESS® steel sleeves, and ONE PRESS® dies, ONE PRESS® works with wire rope ranging in size from 1/4″ up to 1-1/2″ inclusive

The only fully integrated swaging system for Flemish eye wire rope slings, ONE PRESS® is 100% efficient. There is no need for rotating the sleeve or assembly, or multiple closing of the dies. Second stage dies are not required.

Swaging with ONE PRESS® eliminates awkward handling of assemblies, increasing safety and ergonomics, and insures the integrity of the final wire rope slings – without compromise.

This advanced swaging technology works with modern precision swagers, and is designed and engineered for optimal use with Strider’s SMART™, FAST™ and UNIVERSAL™ Swagers.

ONE PRESS® is ideal for businesses that are doing production orders, as well as rigging shops that need to make a single wire rope sling quickly for an immediate lifting requirement.

If your company is having production bottleneck issues, workplace safety concerns, wants to save on expensive electricity or labour costs, or simply needs to modernize in order to stay competitive in today’s market, The ONE PRESS® Swaging System is the safe, fast and reliable smart solution.

The ONE PRESS® Swaging System, including trademarks, intellectual property rights and inventories, is available exclusively through Strider-Resource. For quotations and personal service, contact our ONE PRESS® swaging specialists at 905-859-3901. You can also view our One Press® Swaging System Keynote Presentation.

ONE PRESS® System Advantages

- Efficiency: The unique combination of One Press® Dies and One Press® sleeves simplifies the process of swaging steel sleeves multiple times, using only one swage, in one cavity, using only one set of dies.

- Quality: A steel sleeve swaged only once will not experience the same work (material) hardening as a sleeve hit multiple times.

- Accuracy: There is no allowance for errors. The right sleeve can only be used with the correct rope and the proper dies. Mistakes cannot be concealed through multiple swaging.

- Compliance: One Press® dies are bolted into place for precision, safety and performance. North American and European hydraulic swager press standards require dies to be fixed, rather than floating.

- Safety: One Press® Swaging reduces worker exposure to hand and back injuries, as well as carpel tunnel syndrome.

The One Press® Swaging System will work with different swager brands but will perform optimally in modern hydraulic swagers (precision swagers). Our Universal™ Swagers can also be used with existing dies to swage round steel sleeves, swage sockets and aluminum ferrules.

Learn how ONE PRESS® will give your business a competitive edge

The use of The One Press® Swaging System contributes to improved product quality on a consistent and reliable basis, helping to reduce costs, maintain or increase profits, and maximize efficiency with:

- Less time and skilled labour required to make slings

- Less capital equipment required to make slings

- Reduced chance of injury

- Lower operating and maintenance costs

- Less inventory and storage space required to service customers

- More customers service opportunities

For over 19 years, The One Press® Swaging System has been proven by wire rope sling fabricators large and small, in countries around the world, to be the fastest, most efficient, and the most cost effective method of swaging carbon steel sleeves on Flemish eye wire rope splices.

Swagers

International expertise and innovative advancement in swaging press technology

Universal™ Swagers from Strider-Resource offer swaging press solutions that are faster and more reliable to make your business more efficient and profitable. Serving an international clientele, Strider can help you to find the best options for your business with innovative products and unique features to maximize productivity and safety. Learn more about our advanced line of modern precision swagers.

Smart Swager

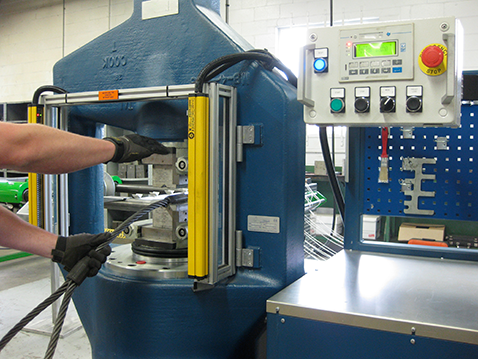

SMART™ Swager with available Swager Guarding™

Features of the SMART™ Swager with Swager Guarding™

Swager Guarding™ allows trained operators to swage wire rope slings without risk of injury caused by pinch points. New and innovative technology permits a full range of wire rope diameters to move freely within the swaging zone. The system automatically stops when the operator gets too close, and easily resets to continue swaging.

Features of the SMART™ Swager with Swager Guarding™

- Incorporates a universal die pocket to accommodate both ONE PRESS® and multi-press dies, which are quickly and easily installed using a modern reliable eccentric clamping system.

- The pump and motor are fully enclosed and insulated.

- The swager operates at a very low noise level of 60-68 decibels.

- The main controls and the electric foot pedal can be repositioned for easy accessibility.

- Stroke limiter and hold modes are easily programmed to save time and energy.

- Production and maintenance tracking is easy as the control system counts and records the total number of swages and operational hours. It records overloads and provides maintenance alerts. Alarms indicate if the oil level is low and if the oil and filter needs to be changed.

For more information on the SMART™ Swager with Swager Guarding™, please contact us today at 905-859-3901. You can also download our sales sheet or view our video.

Fast™ Swager

Swagers engineered and optimized for use of the One Press® Swaging System:

- FAST™ Swager – 385 ton

- FAST™ Swager – 660 ton

Learn more about Fast™ Swagers – contact us today for expert consultation on the best swaging solutions for your business. Call us at 905-859-3901.

UNIVERSAL™ 150 Tonne

Universal™ Swagers by Strider~Resource will accommodate all types of swaging dies, including One Press®, Esco, and European Aluminum for High Performance.

For more information on the Universal™, Fast™, and Smart™ Swager with Swager Guarding™, please contact us today at 905-859-3901.

UNIVERSAL™ 350 Tonne

Universal™ Swagers by Strider~Resource will accommodate all types of swaging dies, including One Press®, National, Esco, and European Aluminum for High Performance.

For more information on the Universal™, Fast™, and Smart™ Swager with Swager Guarding™, please contact us today at 905-859-3901.

UNIVERSAL™ 600 Tonne

Universal™ Swagers by Strider~Resource will accommodate all types of swaging dies, including One Press®, National, Esco, and European Aluminum for High Performance.

For more information on the Universal™, Fast™, and Smart™ Swager with Swager Guarding™, please contact us today at 905-859-3901.

UNIVERSAL™ 1000 Tonne

Universal™ Swagers by Strider~Resource will accommodate all types of swaging dies, including One Press®, National, Esco, and European Aluminum for High Performance.

For more information on the Universal™, Fast™, and Smart™ Swager with Swager Guarding™, please contact us today at 905-859-3901.

UNIVERSAL™ 1500 Tonne

Universal™ Swagers by Strider~Resource will accommodate all types of swaging dies, including One Press®, National, Esco, and European Aluminum for High Performance.

For more information on the Universal™, Fast™, and Smart™ Swager with Swager Guarding™, please contact us today at 905-859-3901.

UNIVERSAL™ 2000 Tonne

Universal™ Swagers by Strider~Resource will accommodate all types of swaging dies, including One Press®, National, Esco, and European Aluminum for High Performance.

For more information on the Universal™, Fast™, and Smart™ Swager with Swager Guarding™, please contact us today at 905-859-3901.

UNIVERSAL™ 3000 Tonne

Universal™ Swagers by Strider~Resource will accommodate all types of swaging dies, including One Press®, National, Esco, and European Aluminum for High Performance.

For more information on the Universal™, Fast™, and Smart™ Swager with Swager Guarding™, please contact us today at 905-859-3901.

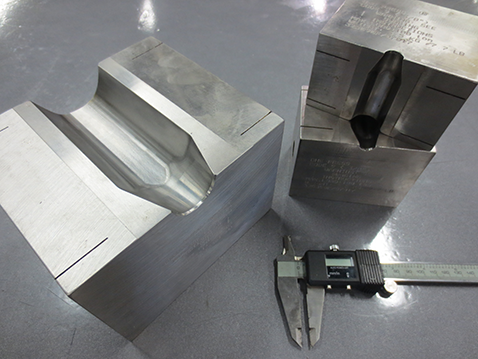

DIES

One Press® Dies are engineered and built to swage One Press® Sleeves from 1/4″ up to 1-1/2″ inclusive in just one press. Using One Press® Dies eliminates time-consuming multi-pressing and second stage die changes.

The efficiency of One Press® allows the dies to be significantly smaller and lighter than multi-press dies, and they are precision cut to ensure fluid metal movement. These dies work with any modern precision/hydraulic swagers, but are designed and engineered for optimal use with Strider’s SMART™, FAST™ and UNIVERSAL™ Swagers.

Die Stock Sizes:

1/4”, 3/8”, 1/2”, 5/8”, 3/4”, 7/8”, 1”, 1-1/8”, 1-1/4”, 1-3/8”, 1-1/2”

For more information on custom die orders, including traditional multi press round sleeve, swage socket, buttons and aluminum and copper ferrule dies, please contact us today at 905-859-3901.

Sleeves

One Press® carbon steel sleeves are designed to swage and hold a wire rope Flemish eye splice with 100% efficiency. All sleeves are fabricated to meet strict quality control requirements and are stamped for easy traceability.

Sleeve Stock Sizes:

1/4”, 5/16” and 3/8” (same die), 7/16” and 1/2” (same die), 9/16” and 5/8” (same die), 3/4”, 7/8”, 1”, 1-1/8”, 1-1/4” 1-3/8”, 1-1/2”

Contact our team today for expert consultation on the best swaging solutions for your business. Call us at 905-859-3901.

Resources

Swager Capacity Guide

| Swage Capacity Shown As Diameters | Swaged Sockets | |||||

Fast™ | One Press® | Standard | Duplex | Ferrules | Buttons | Full Shank | Progressive |

350 Tonne | 1″ * | 1″ | On Request | On Request | On Request | On Request | On Request |

600 Tonne | 1-5/8″ * | 1-1/2″ | 1-1/4″ | 9/16″ | 7/8″ | 3/4″ | 1-1/4″ |

1000 Tonne | 2-1/2″ * | 2-1/2″ | 1-1/4″ | 9/16″ | 1-1/4″ | 1″ | 1-1/2″ |

* One Press® Carbon Steel Sleeves are available in a complete range of sizes from 1/4″ up to 1-1/2″ inclusive.

+ All One Press® Dies are single stage dies from 1/4″ up to 1-1/2″ inclusive. Second stage dies or die change-outs are not required. The specifications above are for One Press® Swaging. The swage capacities of individual Smart™, Fast™ and Universal™ Swagers may be greater when doing multi press swaging.

Smart™, Fast™ and Universal™ Swagers can also be used for multi-press swaging. Dies are available for multi-press sleeves, swage sockets, buttons, and ferrules to fit directly into the standard die holder. Fast™ and Universal™ Swagers with an “All In One” Universal Die Holder accept One Press® Dies and larger die block sizes that fit other makes and brands of swagers.

One Press® Dies may be used in other brands of swagers with or without the use of an adapter or modifications to the existing die holders. Performance will vary due to differences in the speed and efficiency of certain makes of swagers. One Press® Dies are precision dies and are designed to work best in swagers that have accurate tolerances.

*+ Limited by availability of fitting sizes.

Swaging System Comparison

Swager Type | System | No. Of | Swaging Method | Speed & | 2nd Stage |

Fast™ | One Press® Dies | 1 | Compression | A (Highest) | NO |

2 Post Style | One Press® Dies | 1 | Compression | B | NO |

4 Post Style | One Press® Dies | 1 | Compression | C | NO |

Fast™ | 2-3 Pass | Multi | Compaction | D |

|

Fast™ | Standard Die | Multi | Compaction | E | YES |

2 Post Style | Standard Die | Multi | Compaction | F | YES |

Scissor Style | 2-3 Pass | Multi | Compaction | G |

|

4 Post Style | 2-3 Pass | Multi | Compaction | H |

|

Scissor Style | Standard Die | Multi | Compaction | 1 | YES |

4 Post Style | Standard Dies | Multi | Compaction | J (Lowest) | YES |

Fast™ Swagers are available with an “All In One” Universal Die Holder that will hold One Press® Dies and larger die block sizes that fit other makes and brands of swagers.

Dies are also available for multi press sleeves to fit Fast™ Swagers, as well as dies for swage sockets, ferrules, and buttons.

FAQs

Is the One Press® Swaging System available now?

Yes

Is One Press® Swaging for Flemish eye splices?

Yes

Is One Press® more efficient than multi press swaging?

Yes

Are One Press® steel sleeves different from other steel sleeves?

Yes

Do One Press® Sleeves have a distinct shape?

Yes

Are One Press® Sleeves competitively priced?

Yes

Are One Press® Sleeves easily identifiable before and after swage?

Yes

Are One Press® Sleeves fully traceable?

Yes

Are One Press® Sleeves available from 1/4" up to 1-1/2" diameter?

Yes

Are One Press® Sleeves available from U.S. and Canadian stock?

Yes

Is One Press® Swaging proven reliable?

Is One Press® Swaging the first and only one press swaging system for swaging steel sleeves on Flemish eyes?

YES

Is One Press® Swaging System flash free?

YES

Is my satisfaction guaranteed?

YES

Are One Press® Dies required?

YES

Are One Press® Dies lightweight and ergonomically friendly?

YES

Are One Press® Dies available from stock?

YES

Is inspection, service and certification available for One Press® Dies?

YES

Are One Press® Dies competitively priced?

YES

Is it true that One Press® Swaging does not require the use of second stage dies?

YES

Are Fast Swagers available from 165 to 3300 tons?

YES

Are Fast Swagers modern and efficient?

YES

Is Fast Swager installation and training available?

YES

Are Fast Swager spare parts and service readily available?

YES

Are Fast Swagers competitively priced?

YES

Does every Fast Swager include the unique rotating die pocket?

YES

Are Fast Swagers in stock?

YES

Can I see it and try One Press® Swaging for myself?

YES

Does One Press® Swaging improve productivity and efficiency?

YES

Can I increase my sling and assembly production and save money?

YES

Can I use my standard sleeve and socket dies in a Fast Swager?

YES

Is the One Press® Swaging System patented?

YES

Can Fast Swagers also be used for multi pressing of sleeves, sockets, ferrules and buttons?

YES

What is the basic difference between One Press® Swaging and other swaging systems requiring more than one close of the die (multi press)?

- The difference is in the swaging process itself. The One Press® Swaging System compresses the steel sleeve onto the wire rope. Multi press swaging systems compact the steel sleeve on the wire rope. Compaction requires multiple closures of the die. One Press® Swaging requires one and only one closure of the die for 100% efficiency. (The right way, the first time, every time, in the least amount of time.)

- The One Press® Swaging System is protected by U.S. Patents #5,816,094 and #6,032,338 and other worldwide patents and patents pending.

Combined with the unique, modern design features of Fast Swagers, One Press® Swaging helps to overcome many of the “bottlenecks” associated with the fabrication of wire rope slings and bridle sling assemblies in rigging shops.

One press testimonials

Ready to Experience a Better Way to Lift?

Find out more about our products – and download our product guide